Ammonia Screw Compressor Packs produced by J.S.Cooling are built from components manufactured by J&E HALL, Danfoss, Nidec, Hansen and many others. We are the only company in Poland to manufacture ammonia screw compressor packs, which we develop and adapt to dedicated customer needs. The operation of our units is based on automation, so they can fully exploit their power potential by adjusting each parameter one by one, additionally reducing the amount of time spent on servicing the refrigeration installation. The new J.S.Cooling units feature high COP screw compressors and extremely efficient permanent magnet synchronous motors. As chillers are appliances that run continuously, installing a chiller with a lower power consumption and higher efficiency brings significant savings in electricity costs.

Dyneo + motors are ideal for use in chillers thanks to their IE5 Ultra-Premium rating, offering significant savings. They cope seamlessly with varying speeds and loads, which is typical of industrial refrigeration, where demand varies greatly depending on the season and production level. The Dyneo + solution also makes it possible to significantly increase the COP of the chiller. In addition to reducing the carbon footprint, the series offers a TCO (total cost of ownership) that is one of the lowest on the market, as well as a quick return on investment, even in less than one year.

The advantage of Dyneo+ solutions from J.S.Cooling

|

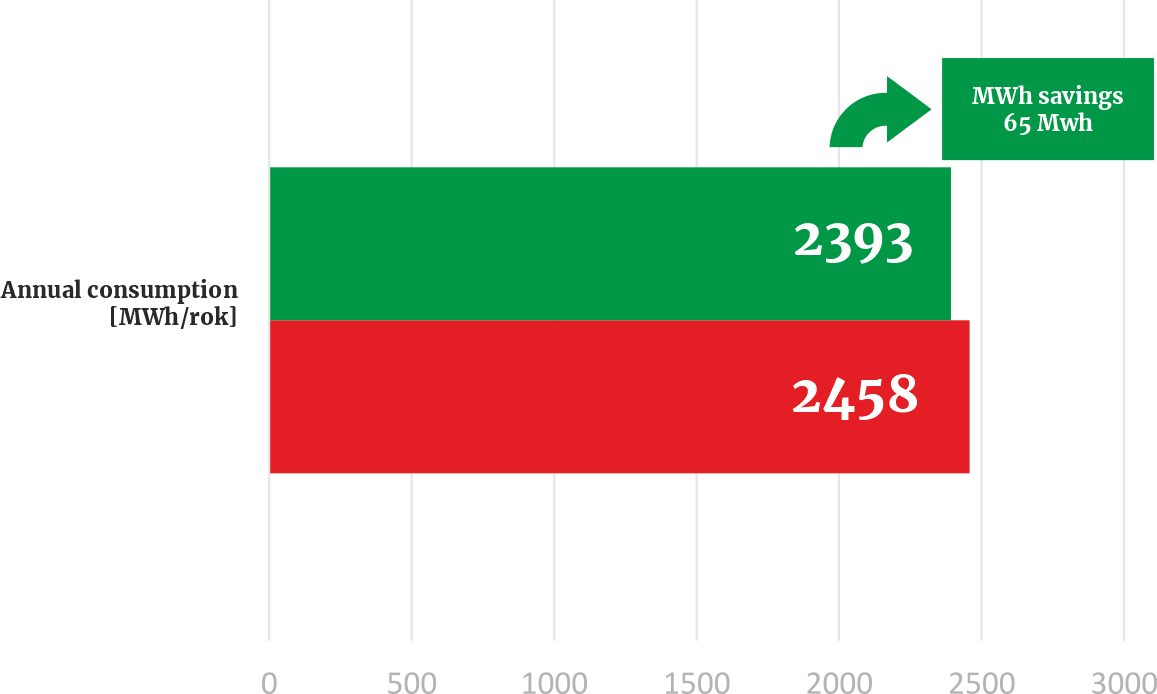

Comparison of power consumption of standard motors and Dyneo+ solutions used in our solutions. |

|

Dyneo+ IE5 synchronous motor with Powerdrive MD2 drive Dyneo+ IE5 synchronous motor with Powerdrive MD2 drive |

Asynchronous motor with generic inverter Asynchronous motor with generic inverter |

|

|

Active energy savings (MWh/year) per engine |

|

|

Total savings from the use of the engine (1 year) PLN |

|

|

Total savings on the use of the engine (10 years) PLN |

J.S.Cooling is the only Polish producer of Ammonia Screw Compressor Packs.

We use modern IE5 Ultra-Premium class motors in our units, which are characterised by:

- Energy saving (use of variable speed and optimisation of mechanical systems).

- Exceptional levels of efficiency throughout the speed control range, especially during lower speed operation when efficiency is higher than with induction motors.

- High energy savings and lower maintenance costs.

- Quick return on investment compared to traditional AC solutions. It is significantly higher than traditional technologies.

- Motor speed adapted to the speed of the machine being driven.

- Potential elimination of power transmission systems.

- Improved performance of the driven machine by increasing its speed.

- Low rotor losses, reduction of mechanical losses.

Advantages of J&E Hall rotary screw compressors

In the latest models of our units we exclusively use screw compressors made by J&E Hall. This type of compressor has many advantages over reciprocating compressors, including higher efficiency, better suited for continuous operation, no vibration, etc.

Dedicated solution

In order to perfectly match the power of the aggregate to the demand, in our offer there are different models. We use compressors and motors of different capacities, followed by dedicated accessories and an oiler. By matching each component to a particular model, electrical power is always used in the most efficient way possible.

Files to download

- Catalog JS.Cooling download files